Lab Coat Fabric: What Material Do You Need? [+ Easy Charts!]

Polycotton or 100% cotton? Flame-resistant or not?

It’s hard to know what lab coat fabric will provide the best protection.

Some materials are great at repelling water but catch fire easily -- melting and causing severe burns along the way.

Others are less flammable but highly absorbent and not great with biological contaminants.

This quick guide will go through:

- The purpose and limitations of lab coats

- The types of fabric used for lab coats

- How to choose the right lab coat material fabric

So let’s get started!

What's the Purpose of a Lab Coat?

Also sometimes known as a white coat, a lab coat functions as protection, identification, and a mark of professionalism for scientists and medical professionals. The white coat symbolises the hope, purity, and transformation that marked the turn of the 19th century, when science first took off as a profession.

In a laboratory, lab coats serve to:

- Protect the wearer's skin and street clothes from contaminants/chemical splashes

- Prevent cross-contamination outside the lab (provided the coat isn't worn outside)

- Provide an easily-removable barrier in case of accidental spills, splashes, fire, or other hazards

- Prevent sleeves and arms from touching containers/chemicals (with the use of knitted or elastic cuffs)

In healthcare, medical professionals in many countries have stopped wearing white coats because of their link to Hospital-Associated Infections (HAIs). Even knowing this though, many patients still prefer their physicians to be in scrubs and/or a white consultation coat as this gives them a greater sense of comfort and confidence in the doctor.

Students in medicine, nursing, pharmacy, and veterinary medicine still wear short white coats as a symbol of their ongoing training and induction into the profession.

Limitations of Lab Coats

Lab coats are meant to be used with all other engineering controls (such as a fume hood, process enclosure, etc.) and Personal Protective Equipment (PPE), not replace them.

Likewise, the use of proper engineering controls isn’t meant to substitute for wearing PPE.

That said, there’s very little testing done on how well the protective clothing holds up under combined research activities in a lab environment. For example, a lab coat advertised as “flame resistant” isn’t necessarily chemical or acid-resistant as well.

Also, even when a lab coat is advertised as flame resistant, this usually only refers to treated cotton that won’t burn in air. It says nothing about how well it’ll protect the wearer against chemical fires.

For those reasons, lab coats are typically the last line of defence and meant as part of a system of established safety protocols and good workplace habits.

Types of Fabric Used for Lab Coats

100% Cotton

Cotton is a popular choice of material for lab coats because of its breathability and comfort. If you’re wearing it as a medical lab coat or consultation coat, this lightweight material will give you a bit of splash protection. Appropriate for use in clinical settings and laboratories where biological materials are present.

Side note: There’s a common misconception that 100% cotton lab coats are flame-resistant. They aren’t.

Untreated cotton will actually ignite and continue to burn during an arc flash, so it’s inadvisable to wear 100% cotton lab coats unless they’ve been specifically marked as flame-resistant. (Check out this video to see an experiment that demonstrates this.) The flame retardant will also wear off over time if the coats are frequently washed.

Polyester

Polyester gives a bit of liquid resistance to the coat and makes it easier to wash and maintain. It’s also cheaper to produce than cotton. But polyester should not be used in settings with pyrophoric chemicals, open flames, or other flammable hazards - it burns readily and will melt, causing severe burns to your skin.

Polyester-Cotton (Polycotton)

Most of the cheaper lab coats you’ll see are a blend of polyester and cotton. It’s breathable, lightweight, easy to launder, and offers some splash and chemical resistance (though this is dependent on the manufacturer).

Although not as soft as 100% cotton, polyester-cotton blends (with no less than 35% cotton) are good for use in an environment where there are no open flames.

Lab coats with polycotton blends are the most cost-effective and durable material when frequent washing is required. Polyester blends can also be treated with wrinkle-free chemical wash, in turn requiring less ironing.

Nylon

Lightweight and strong, this type of material holds up well against damage and the elements. Nylon is also wrinkle-resistant, easy to launder, and offers some protection against liquids (though not as much as polyester).

Like polyester, nylon will melt if ignited and cause severe burns. Some manufacturers will apply flame retardant to nylon lab coats.

Modacrylic

This is a synthetic material that offers good protection against chemicals and solvents. They’re also naturally resistant to flames (including arc flash protection) as they’re difficult to ignite and will self-extinguish.

It can be machine-washed warm and tumble-dried on a low setting. However, modacrylic should not be steamed or washed in high temperatures as it’s sensitive to heat.

Modacrylic tends to shrink instead of melt when exposed to fire, so it’s better than polyester and nylon in that aspect.

Rayon

Rayon (or viscose) is basically made of wood pulp. It’s cheaper than cotton, but similar in that it’s breathable, lightweight, and absorbent -- making it a popular choice for manufacturers looking to add a bit of comfort to their budget-friendly lab coats.

It’s not great against acids (or liquids in general) and catches fire easily unless it’s been treated with a flame retardant.

Polypropylene

This is the material that most disposable lab coats are made of. It’s lightweight and breathable along with its high resistance to absorbing moisture. Manufacturers sometimes add carbon fibres to the polypropylene lab coats to increase this liquid resistance.

The downside is that it degrades quickly when exposed to UV rays and is easily flammable. Polypropylene lab coats are typically used in mostly non-hazardous environments, such as when handling animals or in clean rooms.

Tyvek

This actually describes a brand rather than a type of fabric. Tyvek is a nonwoven material comprising high-density polyethylene fibres (i.e. plastic) that have been compressed. It’s breathable, waterproof, and maintains its strength even when wet.

It’s primarily used when durability and tear-resistance are of extreme importance, such as against biological hazards or fine particles.

Nomex

Nomex is one of the more expensive choices on this list, but it’s best in an environment where there are extreme fire hazards, open flames, and electrical/pyrophoric materials. It doesn’t easily ignite and provides a barrier against the fire and heat. The flame resistance is maintained even when laundered as long as bleach isn’t used.

Nomex is breathable but slightly bulkier than polycotton blends or 100% cotton lab coats.

It offers limited splash protection, but is now often combined with Shieldtec for both fire and chemical resistance.

What Lab Coat Material Fabric is Best for You?

Buying a lab coat begins with knowing the types of hazards you may face. For example:

- Are you working with chemicals, biological agents, or radioisotopes?

- Does your lab work involve handling animals such as mice?

- Are there flammable or pyrophoric materials?

- Is there a high risk of spills, splashes, and splatters?

- Is there a possibility for the spread of contamination?

There are exceptions, of course. Certain healthcare professionals wear white consultation coats mainly as a form of identification or a symbol of trust -- not so much for protection.

But in general, understanding the possible dangers will influence the choice of lab coat material fabric, along with the design of the lab coat and other PPE required.

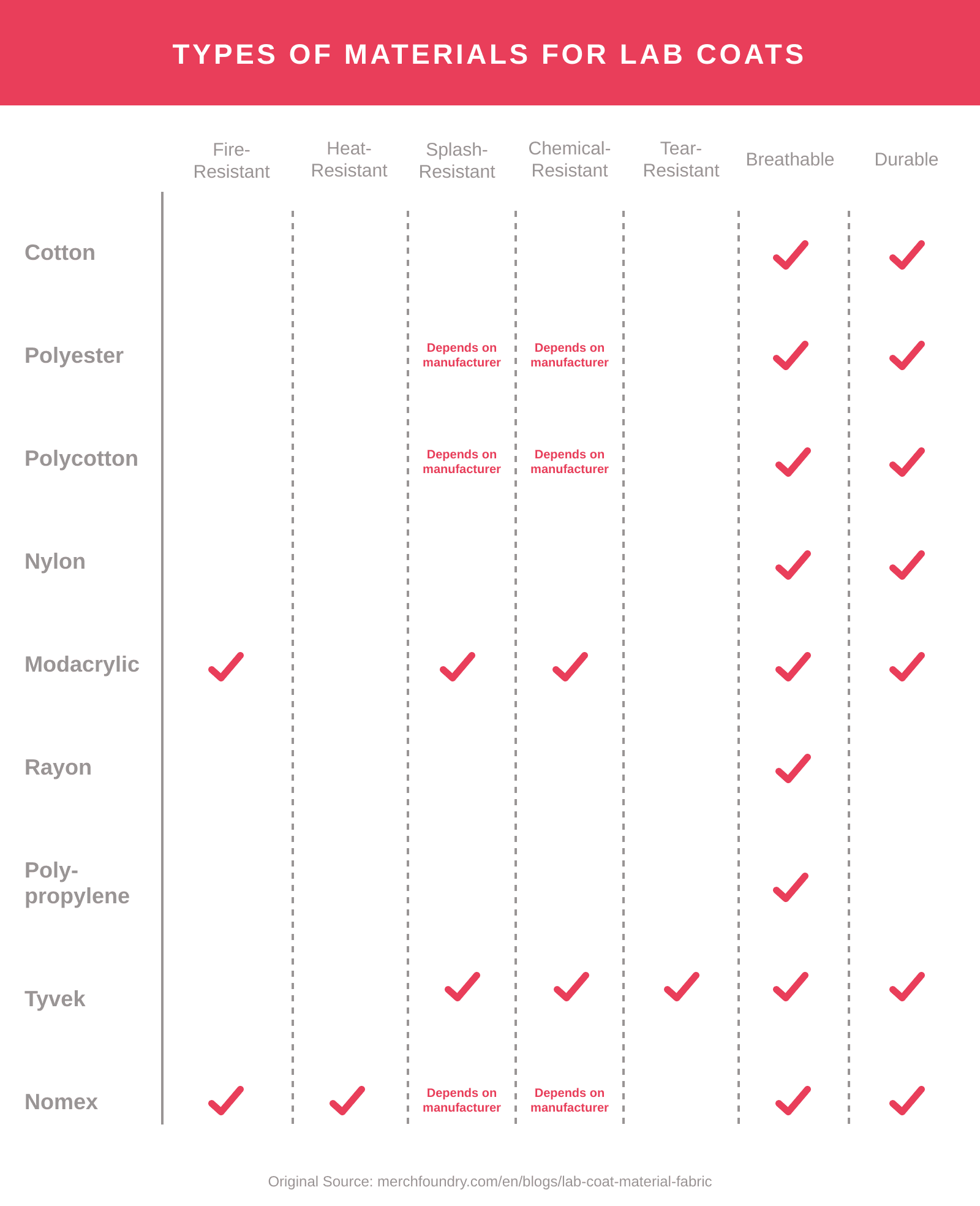

Here’s a quick infographic to help you decide what fabric you need:

Manufacturing plants, hospitals & labs use MF to automate orders and manage their uniforms.

Learn more